Offer 374626

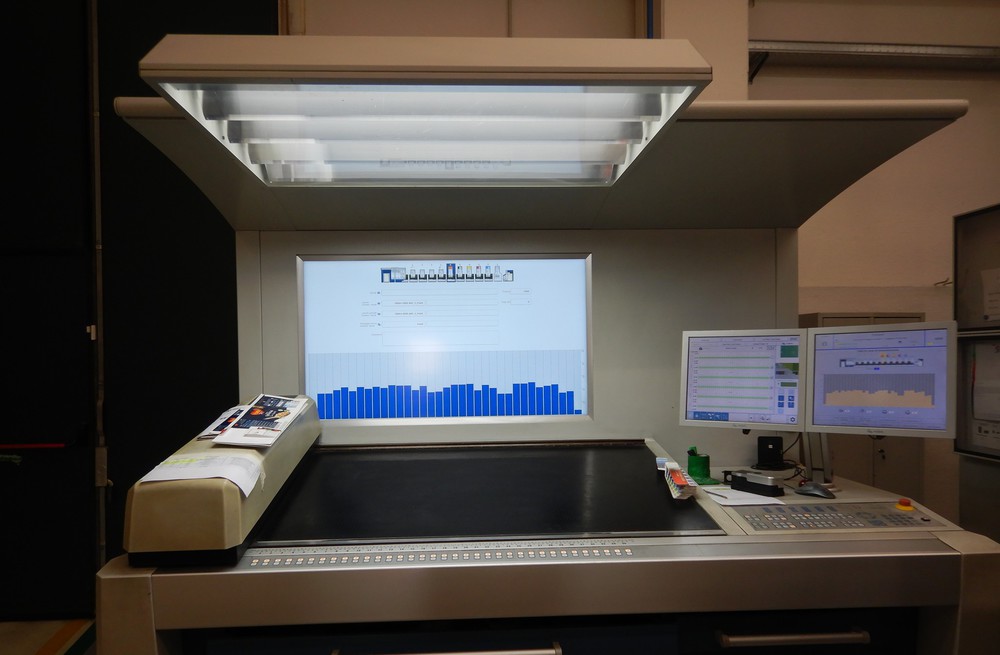

KBA-RAPIDA RAPIDA 106-6+LTTL (2000+) from 2013

6 Color

Offer Details

| Offer Number: | 374626 |

|---|---|

| Brand: | KBA-RAPIDA |

| Model: | Rapida 106-6+LTTL (2000+) |

| Manufacturer | KBA-RAPIDA |

| Condition: | Good |

| Year: | 2013 |

| Incoterm: | |

| Cylinders Condition: | |

| Under Power: | No |

| Still in production: | No |

| Test possible: | No |

| Complete and in working condition: | Yes |

| Availability: | 10/2024 |

| Counter: | 325 mio |

| Machine number: | |

| Description: | QualiTronic Quality Pass - Creation of colour measurement reports for quality controlWall screen for visualisation of all press processesQualiTronic KBA Control Strip 2012QualiTronic ColorControl (straight printing) - Inline ink density measurementQualitronic PSO match (Colour control according to the PSO)ErgoTronic ColorControl - Automatic ink density measurement along x and y axis at the ErgoTronic consoleErgoTronic Lab - Color measurement and control acc. to Lab valuesErgoTronic ICR (register control)incl. one pneumatic plate bending device at the galleryAdditional package "High efficiency antistatic equipment"SIS – Sensoric Infeed System, sidelay-free lateral sheet alignment with automatic format setting via ErgoTronic console, lateral alignment occurs by means of movable infeed gripper barACS (Air-Cleaning-System)KBA VariDry BLUE IR/HotAir/UV in delivery and extended delivery (ALV3)Intercommunication system between infeed and deliveryAdditional package "Active air-cooling for control cabinets"Varnish supply and cleaning system for water-based varnish and UV-varnish, with operation via control console, pump output dependent on viscosity (HARRIS & BRUNO)Drying unit (T) for straight-printing presses2 Coating unit (L) with chambered doctor blade systemErgotronic LAB (Colour measurement and control according to LAB values)Extended delivery 3800mm (ALV 3)Roller covering for alcohol-reduced printingInking unit temperature control without ink duct roller cooling, incl. High-tech combi-cooling unit, air-cooled (TECHNOTRANS)Varnish supply and cleaning system for water-based varnish, with operation via control console, pump output dependent on viscosity (HARRIS & BRUNO)Additional anilox roller (according to KBA standard)IPA reduction < 5% incl. microfilter "beta.f" (TECHNOTRANS)KBA VariDry IR/HotAir in the drying unitMotorized console height adjustment with memory functionMachine oil for drive gearsCIP Link with online connectionAutomatic feeder height adjustmentAnilox loader – Anilox roller change for 3 anilox rollers in the coaterKba PressSupport 24 Sheetfed with internet connection for remote maintenance and software updatesCleanTronic Synchro for parallel washing for rollers and blankets cylindersVARIDAMP alcohol dampeningPWVA Plate changeCoaterChromed cylindersAll washing devicesChambered doctor bladesAnilox rollersUltrasonic double sheet controlITC Ink temperature controldismantledIn stock |

Technical details

| Max. paper size | 740x1060 mm |

|---|---|

| Smallest size | 340x480 mm |

| Image area | 730x1050 mm |

| Plate size | 795x1060 mm |

| Speed | 18.000 sh/h |

| Power consumption | 155 kw (with IR dryer) |

| Length | 14000 mm |

| Width | 4001 mm |

| Height | 2280 mm |

| Weight approx. | 64000 kg |

| Colors | 6+L |

| HS Code | 84431300 |

| transport by sea | 5x40' HC |

PRICE: Upon request

Images