Offer Number |

356371 |

Manufacturer |

MKW |

Model |

UT 16 B3-GS |

Year |

2012 |

Counter |

|

In Production |

NO |

Upon Request

Description

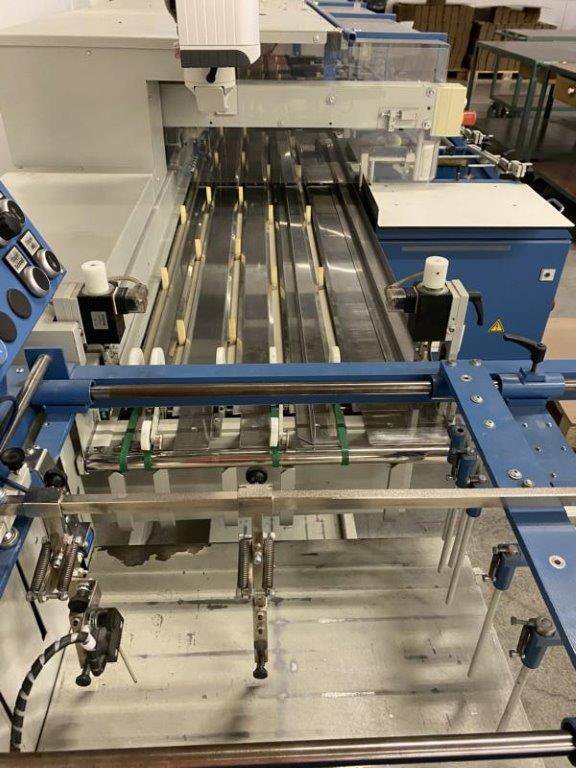

With 16 stations in normal operation<>- Format 10 x 14 cm to 35 x 50 cm<>- Large stack with max. 70 cm stack height<>- Paper weights approx. 14 - 1000 g/m²<>- Toothed belt transport table for continuous paper transport<>- Toothed belt table radially adjustable for precise sheet placement<>- Adjustable tilting suction cups for optimal paper pick-up<>- Pressure vacuum generator in soundproof housing<>- Blowing air device with adjustable automatic front blowers<>- Blowing air device with adjustable height-adjustable side blowers<>- Blowing air device with adjustable stretching air<>- Electronic machine control via industrial PC<>- High-quality 12.1" color display (TFT) for safe and clear operator guidance<>- Self-calibrating electronic missing and double sheet control per station<>- Missing and double sheet controls can be parameterized on the operator terminal<>- Missing sheet repetition<>- Tandem function for double use 2:1 (normal operation only)<>- Dynamic station selection for optimized pre-loading for the next order<>- Automatic activation and deactivation of the preselected stations<>- Possibility of inserting at any station<>- Insertion change function at any station<>- Cardboard change function at any station<>- Speed display with continuous adjustment<>- Pre-selection counter with adjustable intermediate stop for number of sets and stop time<>- Edition counter with emptying of the transport table after the number of sets has been reached<>- Maintenance counter to display the maintenance intervals<>- Total counter to display the total running performance<>- Special counting functions with combination option<>- Delivery control for interlaced delivery with adjustable set interval<>- Storage option for repeat orders<>- Transport table illumination with fluorescent lamps<>- Test programs for service and maintenance work<>- Energy saving system with automatic activation and deactivation of all drives<>- Automatic activation and deactivation of the required Pressure-vacuum generator<>- Jam control above the transport table<>- Possibility of manual feeding on the right-hand side<>- Ejection station including empty station on the delivery AW 3 (35x50)<>(for ejecting faulty sets)<>- Delivery shaker system integrated, servo drive ASS i 2 Q Servo<>(for normal and interlaced delivery, including delivery shaker)<>- Manual feeding station on the left-hand side HV 2 (70x50)<>(including automatic station control in the event of incorrect operation)<>- Lift control of the delivery rollers AHB<>(for different formats per set and folded sheets)<>Special features:<>- Two separate main drives for the suction rod Synchro-HA<>(15 + 15 stations, automatic activation when required,<>to increase production speed)<>- 15 x plug-in bulkheads for DP conversion<>- 15 x plug-in F/D controls for DP conversion<>- foldable transport carriers for DP conversion<>(MKW patented system)<>Customer-specific options for MKW RAPID UT<>- Special program: block or pool program SOFU-BK<>(process control for special packaging)<>- Special program: multiple edition SOFU-WH<>(process control for multiple edition functions)<>- Special program: calendar division SOFU-KT<>(process control for calendar or set division into e.g. 2 parts)<>Alternative to delivery shaker:<>1 high-pile delivery type MKW RAPID HA 570 Q-UT<>- Open format 10 x 14 cm to 70 x 50 cm<>- High-pile delivery up to max. 60 cm stack capacity<>- Plain text display for operation and monitoring<>- Delivery with offset function<>- 2 mobile interchangeable plates

Technical Details

- Max. book size: 350x500 mm

- Min. book size: 100x140 mm

- HS Code: 84439959 HS Codes Classification of Other

Offer Details

- Brand: MKW

- Model: UT 16 B3-GS

- Condition: Good

- Year: 2012

- Country: Europe

- Incoterm: Free Carrier

- Under Power: NO

- Still in production: No

- Test possible: No

- Complete and in working condition: Yes